Ergonomic workplace injuries have accounted for more than half of emergency room visits in recent years, according to the U.S. Bureau of Labor Statistics. To help combat the prevalence of these injuries, innovative camera-based applications are available to provide in-depth evaluations of an employee’s job functions and physical movements while conducting their role. These systems leverage recordings of employees performing their tasks to help assess overall safety data and prevent future injuries without causing workflow disruption.

Innovative Solutions

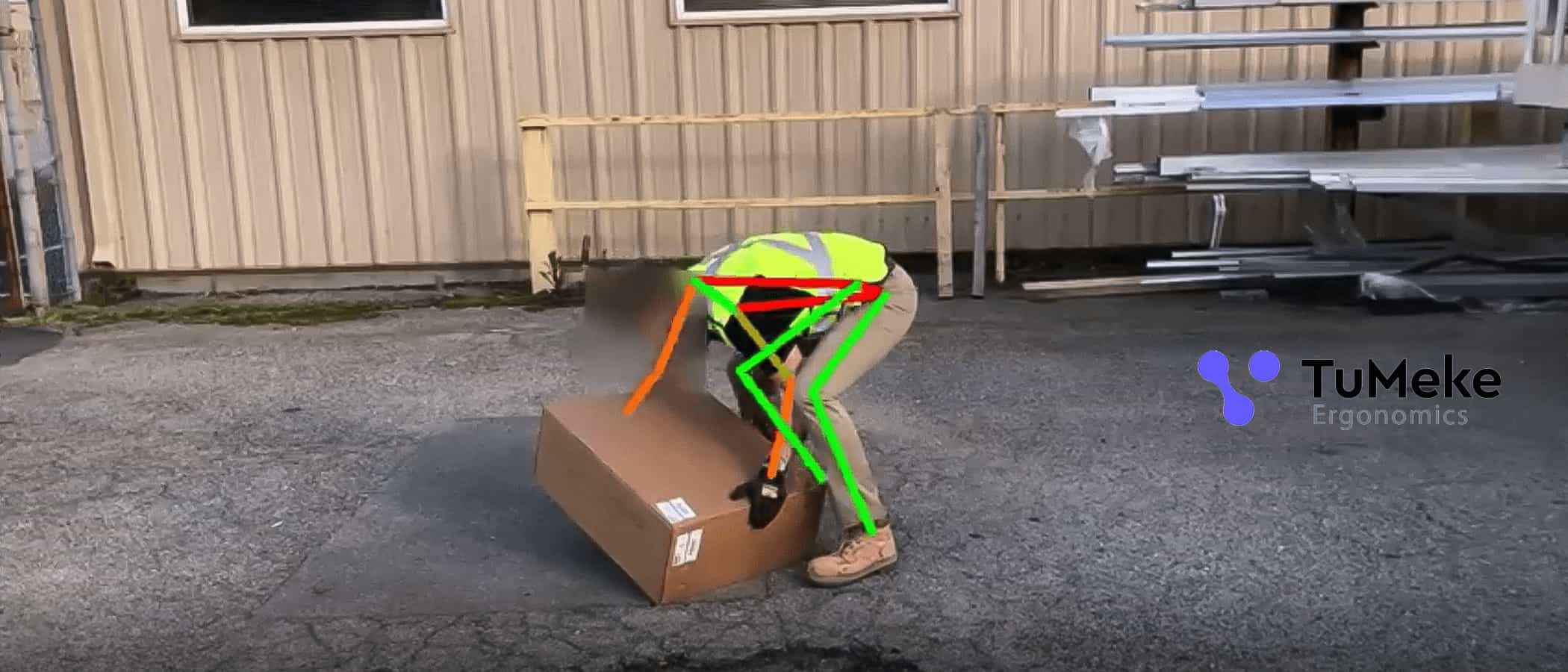

When utilizing technology vendors such as TuMeke Ergonomics, a video of a worker performing their task is uploaded into the analytics platform. Using motion-capture artificial intelligence (AI) technology, the risks associated with the task are captured in the video and calculated. TuMeke’s platform then provides an in-depth analysis that includes risk scores and videos with color-changing elements to depict risk severity and further analysis of the associated risk.

Amerisure’s risk management team recently leveraged its partnership with TuMeke Ergonomics to document the need for a policyholder safety grant through the Michigan Occupational Safety and Health Administration Workplace Improvement to Safety and Health (MIWISH) Grant Program. As a result, Granco Clark, a global leader in the aluminum extrusion industry located in Belding, Michigan, will receive state funds to improve workplace safety.

Analysis & Safety Grant

The safety grant came to fruition when discussing ergonomic risks during a safety committee meeting with Granco Clark.

“When Amerisure’s risk management consultants recommended the concept of leveraging TuMeke Ergonomics to validate the need for a safety grant, the company was immediately elated by the idea,” said Eric Austin, Amerisure risk management expertise specialist. “Together, Granco Clark and our risk management experts conducted an analysis of the areas of work in need of additional safety measures for the grant application process.”

The production role that was analyzed at Granco Clark’s jobsite occurs when the employees manually lift metal components weighing as much as 50 pounds and assemble them onto a large machine that contains as many as 2,000 parts. According to OSHA, manual lifting accounts for a significant amount of human suffering, productivity loss, and economic burden each year.

Following the assessment and application, a grant was approved for the purchase and installation of a jib hoist — a crane with a horizontal arm known as the jib or boom — at Granco Clark. The jib hoist lifts the parts and swivels to move them from workstation to workstation, and then holds them in place for assembly.

The state of Michigan will cover approximately half the cost of the jib hoist for Granco Clark.

Ergonomic Safety Programs

The assessment and measurement of ergonomic risks can help reduce injuries and control workplace losses. Coordinated through Amerisure’s highly trained risk management consultants, policyholders have access to a pre-paid program and collaborative solutions to improve worker safety.